valve seal leak test|valve testing standards pdf : agencies Learn more about the common signs valve stem seals are leaking, how to proactively check them & the most common causes of bad valve stem seals in applications. WEBClub worth €90M. Starting XI average age 26.09. Whole team average age 26.88. Captain J. Worrall. Short free kick M. Gibbs-White. Long free kick M. Gibbs-White. Left short free kick M. Gibbs-White. Right short free kick M. Gibbs-White. Penalties M. Gibbs-White.

{plog:ftitle_list}

Trending - GoreSee - Death is Watching over You

Performing a compression test will usually indicate if the piston rings are worn out or not. A low pressure reading usually points to a worn-out piston ring, whereas a higher reading that is near the normal range can point . Learn more about the common signs valve stem seals are leaking, how to proactively check them & the most common causes of bad valve stem seals in applications.This class establishes the maximum permissible leakage generally associated with commercial double-seat control valves or balanced single-seat control valves with a piston ring seal and .Table of Contents. Symptoms Of A Bad Valve Seal. 1) Blue Smoke From Exhaust. 2) Oil Clogged Spark Plugs. 3) Rough Idling. 4) External Oil Leaks. 5) Loss of Power. 6) Bad Oil .

Visible leaks anywhere in the valve body/bonnet assembly. Leakage via static seals (packing) and gasketed joints, except where permitted by design the test standard. Common industry guidelines for pressure testing valves can be . This video explains the most common bad valve seals symptoms to look for. We will also talk about the valve seals' location, function, replacement cost, and how to test them.

Valve seat leakage tests are required for pressure relief valves. Backseat tests are required for valves with a backseat element, including gate and globe valves. Closure tests .How to Check If Your Valve Stem Seal Is Faulty. Step 1. Step 2. Step 3. Step 4. Step 5. How to Prevent Valve Stem Seal Leaks. Customized Valve Stem Seals. 6 Signs Your Valve Stem Seal Is Leaking. Valve stem seals control oil .

valve testing standards pdf

There are many possible causes of burning or leaking oil, including bad valve guide seals, bad piston rings, bad front or rear main seals, bad camshaft seals, head gasket leaks, and incorrect oil viscosity, to name a few. By measuring the pressure within the cylinder, this test can reveal if there are any leaks present that may be caused by faulty seals. . Conduct routine checks to identify any signs of wear or damage to the valve stem . PAY IT FORWARD . . . Please help me keep all my resources FREE for everyone to learn from and use. DONATE any amount here https://www.paypal.com/donat.

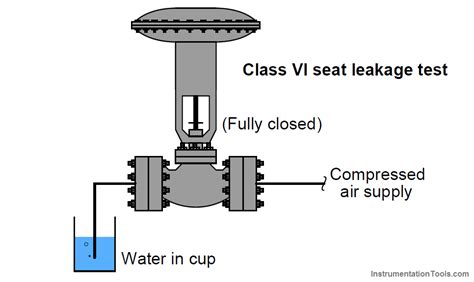

Valve leakage is tested using either a hydrostatic test (i.e., the test medium is a liquid, such as water or kerosene) or a pneumatic test (the test medium is a gas, such as air or nitrogen). Zero leakage is rarely if ever possible, so the standards define the maximum allowable leakage (MAL) for valves under the specified testing conditions.

A pressure test in excess of the cold working pressure (CWP) rating of the valve for the purpose of validating the soundness and strength of the valve pressure-containing structures. 3.9 visually detectable leakage Leakage during a valve pressure test, either through or past a pressure boundary or closure member that is validated by normal vision. A stuck open valve can also cause a vacuum leak since it is supposed to be mostly closed when the engine is idling. 3 Methods To Know if a PCV Valve Has Failed . Test for Vacuum ; There are several methods to test if the PCV valve Has failed. The most common method is to remove the intake hose, start the engine, and check the vacuum.So you have to perform seat leak test with 6880.30 psi. Valve Seat Leak Test Duration. ASME b16.34 require the seal leak test be performed 15 seconds for valves with size less than 2 inch and 30 seconds for valves between 2 1/2 to 8 inch, 60 seconds for valves between 10 and 18 inch and 120 seconds for valves greater than 20 inch. A cold engine test is definitely the best way to answer the question of how to tell if valve seals are leaking. If you leave a car sitting for a long period of time or overnight, the top of the head of the valve cover will remain some left-over oil, and next time you drive, the oil ends up stucking down at the bad seal and creates blue smoke .

Valve pressure test by Valve Testing Board refers to the valve body strength test. Leak test refers to the tightness test of the sealing surface. These two tests are the inspection of the main performance of the valve. The test medium is generally clean water at room temperature, and kerosene can be used for important valves.7.1.5. Testing Procedure. Manufacturer instructions and guidelines shall be taken into consideration. 7.1.5.2 Valve Backseat Test. 7.1.5.2.1 The backseat test is required for all valves, except for bellows seal valves, that have the backseat feature and shall be performed by applying pressure inside the assembled valve with the valve ends closed, the valve fully open, and the . This test ensures that the backseat can provide a tight seal, preventing leakage around the stem packing area, which is particularly important in high-pressure applications. . How can control valve leakage testing contribute to overall process efficiency and safety?

These are the valve stem seals or just valve seals for short. Signs the Seals Have Gone Bad. Now that you know how they work, identifying the symptoms of a failed seal is fairly easy. . or you will have to perform what is known as a leak down test. Mobile Oil Company has a good overview of the leak down test. Is It Safe to Drive With Bad Seals? I've used paint thinner (mineral spirits) in the combustion chamber, looking for liquid that would get into the port past the valve seal. Haven't done it by filling the port and looking for liquid in the chamber. I figure the valve--in operation--is sealing the chamber, not the port. Also eliminates leakage (and mess) past the valve guide/valve . Diagnosing Faulty Valve Guide Seals Compression Test. A standard compression test on all cylinders determines if pressure is leaking. Engines with worn valve guide seals often have one or more cylinders with significantly lower compression readings compared to the others. A wet compression test can provide further accuracy.

Another great option in the best oil stop leaks additives category is the ATP automotive re-seal stops leaks. ATP is also a renowned company for oil stop leak additives and is mostly recommended due to its amazing performance. The additive performs exactly what it is formulated for, preventing corrosion, leakages, and rust. .

The intent, when pressure testing a relief valve, is not to check for leaks, but to test the pressure set point of the valve by gradually adding pressure to the relief valve until it lifts the valve off of the seat. A leak test, on the other .

However, it lacks specific test parameters for the number of test cycles required or the travel distance, so it is hard to compare the leakage results among different valve designs. FCI 91-1 was created by the Fluid Control Institute and is more closely aligned with the leak detection and repair requirements mandated by the Environmental . Possible duplicate of Reliability of water test for valve seal . And is a little leak like 1 drop every few minutes acceptable? Or should it have no visible leak for x amount of time? The video explains this quite well. You're best off waiting for something like 30-40 minutes in order to see if the meniscus has dropped. You should also .Class III - Valve Leakage Classifications. Intended for the same types of valves as in Class II. 0.1% leakage of full open valve capacity; Service dP or 50 psid (3.4 bar differential), whichever is lower at 50 to 125 o F; Test medium air at 45 to 60 psig is the test fluid; Typical constructions: Balanced, double port, soft seats, low seat load .

Can the TURN-AROUND-TESTER™ perform a low-pressure seat leakage test on control valves? Clark Turner addresses this question in a clip from our LIVE Q&A on t.Required for all valves that have the backseat feature, except for bellows seal valves. This is a feature that allows valve packing to be replaced while it is in service. . The Closure Test or Valve Seat Leak Test is performed after the successful completion of the Valve Body Test/shell test. One side of the valve inlet or outlet shall be .

valve seat leak test procedure

Leak down test results are typically represented as a percentage, indicating the amount of pressure that is lost from the cylinder. Ideally, you want to see a leak percentage under 10 percent, which could be noise or a slight ring or valve seal leak.

Leakage Class Designation Maximum Leakage Allowable Test Medium Test Pressure Testing Procedures Required for Establishing Rating; Class I: XXX: XXX: XXX: No test required provided user and supplier so agree: Class II: 0.5% of rated capacity: Air or water at 50-125 F (10-52C) 45-60 psig or max. operating differential whichever is lower Water Testing Cylinder Head Valves is One of the most efficient and easiest ways to diagnose leaky cylinder head valves. We tested cylinder head valves for l.FITTING LEAK TEST REPORT GROUND‐BASED CRYOGENIC LEAK TEST OF FITTINGS FOR CRYOGENIC FLUID MANAGEMENT AUTHORS Jared Sass, NASA, NE‐L2 Angela Krenn, NASA, UB‐G Cryogenics Test Laboratory Kennedy Space Center, FL TEAM MEMBERS Adam Swanger, NASA, UB‐G James Fesmire, NASA, UB‐G Will Reaves, LASSO

The extent to which control valves leak can vary quite a bit from one valve to another, particularly when different seal types are involved. This is why ANSI/FCI 70-2 is important - it defines benchmark standards for seat tightness of control valves in the form of maximum allowable leakage under defined test conditions. During the valve . Fitment: IPR Valve Air Test Fitting and Oil Rail Adapters perfectly fit for Ford 6.0L powerstroke diesel high pressure oil system; 6.0 IPR Valve Socket is compatible with Ford 6.0L and other diesel engines, and IPR Valve Seal Kit 3C3Z9H529A, AP0035, for use with AP63417, 1846057C1, 5C3Z9C968CA, W3250216 and HTV102 IPR Valve, found on 2003-2010 Ford .

3.9 visually detectable leakage. Leakage during a valve pressure test, either through or past a pressure boundary or closure member that is validated by normal vision. 5.9 Test Leakage. 5.9.1 Shell, Stem Seals, and Backseat. 5.9.1.1 For shell tests, visually detectable leakage through the pressure boundary walls and any fixed body joint is not .

how to calibrate a rockwell hardness tester model hr-150a

valve leak tester

webWe would like to show you a description here but the site won’t allow us.

valve seal leak test|valve testing standards pdf